What happens after I receive an Etsy order

May 14, 2020 | 5 minute read

This post is aimed at bringing transparency to what happens on the backend after someone purchases a candle from me. Many of the companies I admire (Everlane, Slack, and Carta) are very transparent in how they operate. With a hope to one day run a business that’ll be a fraction of the size of theirs, I think I should practice the walk and imitate parts of these companies that I find great. So here goes.

The order comes in. My phone vibrates and emits the “cha ching” Etsy sound.

I do a quiet fist pump, get out of my chair, and take a lap around my work vicinity. Note I started this Etsy shop mid-COVID-19 lockdown, so really it’s just a lap around the blue section below.

I kinda just pace around the blue circle.

If the Etsy order comes in during the work day, I’ll continue work and wait until later that night before pulling out my materials to start candlemaking.

Night time comeths.

It’s time to make the candles! I start off the process by doing some quick ingredients planning.

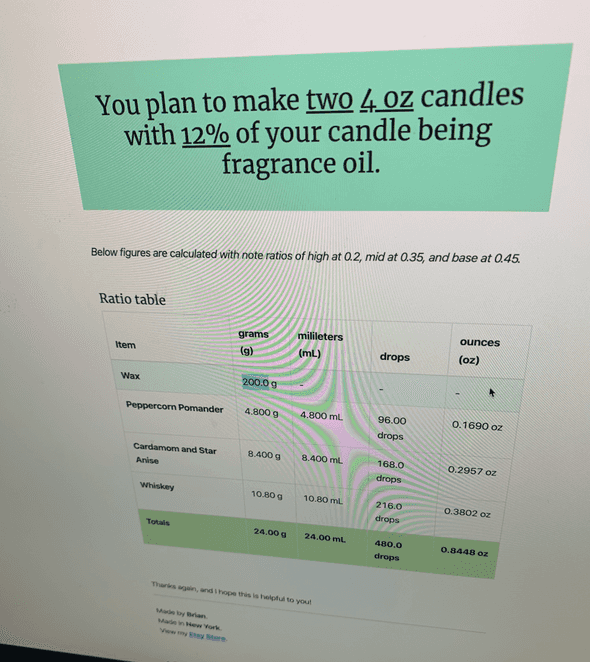

I calculate out how much fragrance oil and wax I need. This used to result in doing some simple math conversions on a sheet of paper, but then I realized that I was essentially re-computing similar ratios over and over again.

So instead, I ended up creating a simple fragrance calculator to help me calculate the ratios. I think this has been helpful to others. I’ve shared pretty consistently with others in r/candlemaking.

I was making a Peppercorn and Pomander, Cardamom and Star Anise, and Whiskey candle for some friends. :)

Now that I have the amount of wax and fragrance oils I need, I start setting up my supplies. This step usually includes:

- Measuring out the needed amount of wax with my trusty scale

- Pasting down wicks in glass amber jars, then fixing the wicks with wick holders

- Drying out glassware (erlenmeyer flasks and graduated cylinders)

- Setting up a double water boiler apparatus

My old kitchen counter. I've since moved to an apartment that has more space.

😅

Now that I have everything set up, I start pouring the wax into a candle pourer that’s floating within the double water boiler. The heat from the water will transfer to the candle pourer, which will then transfer to the wax and begin melting it.

As this is happening, I start mixing together the fragrance oils. I add 12% of the container volume of fragrance oil. So if I was making a 16 oz candle, 1.92 (16 * 0.12) oz of it would be allocated for fragrance oils. Then of this 1.92 oz, I’ll further divide into amounts for the high, mid, and base notes, with each respectively being 20%, 35%, and 45% of the 1.92 oz.

So if I were making the Paradise candle, it’d be: 0.384 oz (1.92 * 0.20) of Pipe Tobacco, 0.672 oz (1.92 * 0.35) of Coconut Bourbon, and 0.864 oz (1.92 * 0.45) of Leather fragrance oil.

I mix the measured out amounts into an erlenmeyer flask.

Now I take a quick check on my wax. The wax has now fully melted, and is at 180 degrees F. It’s at this point when I turn off the burner, and I start mixing in my mixed fragrance oils into the wax. I give the mixture of wax and fragrance oils a good two to three minutes of firm mixing.

After mixing, I pull the candle pouring container out of the water and let it cool.

It’s at this point that I’d start preparing supplies for my next batch of candles. If the Etsy order purchase contained a different candle, I’d have to make that one in a separate batch.

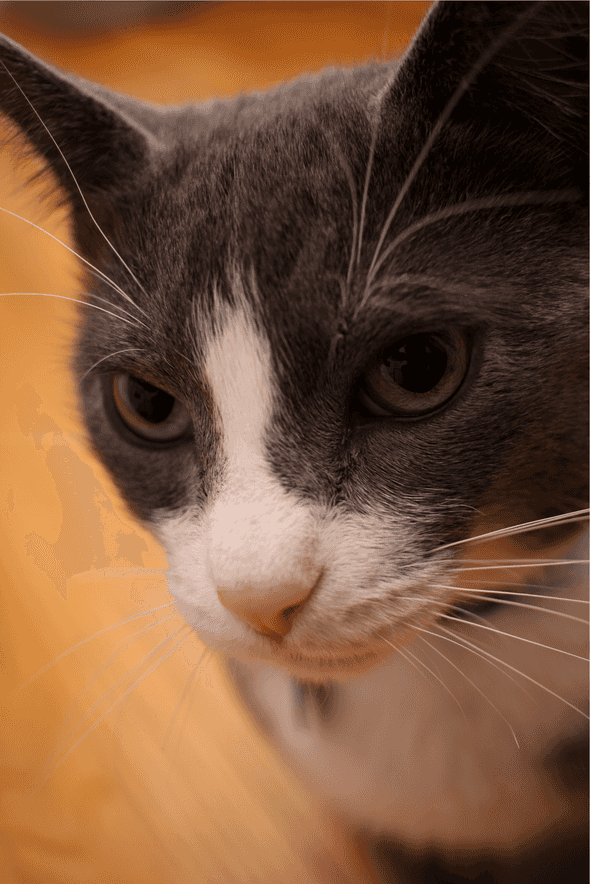

If the Etsy order only contained one candle, then I’ll spend this downtime by bothering my cat Toby.

Toby wondering why his living quarters all of a sudden smells like peppercorns.

Now I come back and check on the wax.

The wax is now approaching 100 degrees F. It’s at this point when I start checking the temperature more frequently. When the wax starts to become visibly more viscous, I will pour it into its candle jar container.

This part is probably my favorite of the candle-making process. In my opinion, getting the timing correct here is where finesse comes in. The end look of your candle largely depends on what temperature you pour the wax out at. If you pour at too high a temperature, the tops of the candle won’t have a silky smooth finish. If you pour at too low of a temperature, it’s likely that air pockets will form and the structure of your candle may be porous, resulting in lumpy wax formation.

Side note: I wrote two other blog posts detailing my tests and experiments with working with Soy Wax, and they both go over why pour temperature is crucial. They are: Working with 464 Soy Wax and Burning 464 Soy Wax

If you do pour the wax outside of the prime temperature band, the quality of the candle is still good, it’s just that an extra treatment is needed to help smooth out the top. The candle will still burn just as fragrant as it did without this extra treatment.

Okay - now we have the wax cooling. What’s next?

Labeling is next. As of now, I handwrite the labels for all my candles. This can be a somewhat tedious process as it’s difficult to maintain consistent handwriting over many writes.

Example of the handwritten labels I produce

I dice up the cardstock paper, and I start to freehand the fragrances of the candle.

Getting this part right is the most stressful part of the Etsy order. It’s very easy to mess up writing this label, and it sucks to have to start over. Anyways, once I finish writing the label, I apply double-sided tape against the back of the label and stick it against the candle jar. I make sure that it’s applied on straight and that it has no excess tape is sticking out the sides.

Why not just use stickers? As a matter of fact, I hope to use stickers in the future. But for now, I don’t know how to get the look I want into a sticker form. I’ve found that stickers can be less forgiving in terms of both design and application. If I mess up applying a sticker, I’ll have to remove all the stickiness from the sticker. If I mess up the design on a sticker, I’ll have to wait another week to get stickers re-edited, printed, and shipped. The additional overhead and constraint in iteration cycle simply makes printing stickers not worth it for me right now.

Now we start to prepare the packaging. This part I’ll omit for now. :) I’d like to keep this part as a surprise. I promise it’s not because I’m hiding some nefarious practice. I’m not elaborating on my packaging because: - it’s something that is likely to change in the future as I’m still working through the unboxing experience. - it’ll take away from the story of the candle that was outlined above. - I want some element of surprise left for the purchaser.

I do outline some of my thoughts behind packaging here if you are reallyyy curious.

Anyways, that concludes what I have to say about what happens over at thoughtfulcandles when an Etsy order comes in.

I have a lot of fun making candles, and I hope to get the opportunity to make one for you (reader, I’m pointing at you!) someday.

Something about creating physical products, that others enjoy, really makes this process fun.

I hope you enjoyed our story, and thanks for reading all the way through!